INGEDE News December 2023:

Adhesives can create problems in paper recycling

- Calendar of Events

- Customer complaint: Sticky stains in the paper

- Stickers are a permanent source of stickies

- Adhesive tests: Many packaging tapes are good

- Blue sale slips: Dispose with residual waste!

- Andreas Rauscher is new Chairman of INGEDE

- Imerys is new INGEDE Silver Partner

- Dramatic decline in the production of graphic paper

- Intergraf: Keep printed package leaflets for medicines!

- Apply now: European Paper Recycling Awards!

- SUBSCRIBE now: to our monthly newsletter!

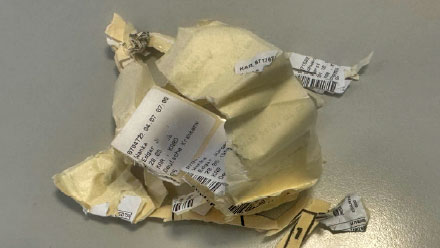

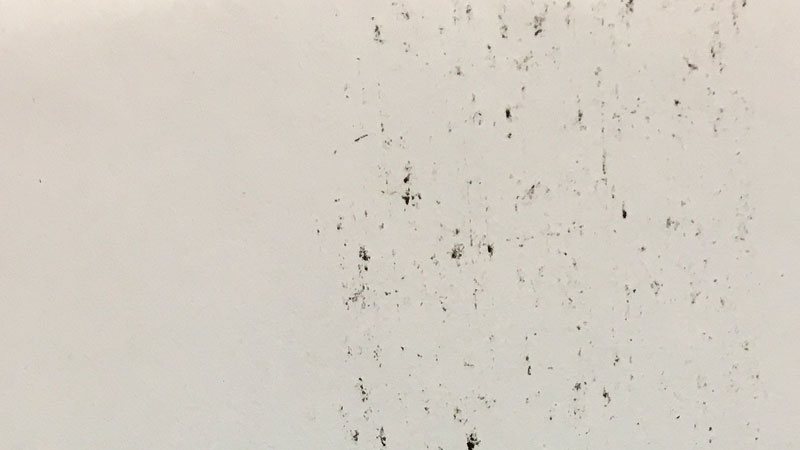

Customer complaint: Sticky stains in the paper

Adhesives from return labels cause considerable losses in the production of recycled paper

Adhesives hold the world together, as well as countless paper products. But adhesives are one of the biggest problems in paper recycling. A paper mill has just been confronted with a major complaint after some damage caused by adhesive residues remained undetected during quality control of the finished paper. These adhesives came from return labels from a large online mail order company and had presumably ended up as misprints in large quantities in the paper for recycling. Such mass incidents in particular can often only be discovered after the fact, after the damage has already occurred – and they expose products that otherwise contribute to the adhesive load again and again without being detected.

In most cases, the optical sensors find the defects: Sticky contaminants on the drying cylinders and the doctor blades that clean these cylinders repeatedly lead to damage in production – for example, pieces fall onto the paper web and stick it to the next layer during reeling. When rewinding and cutting to the format required by the customer, it then happens: a hole tears into the web at the glued point and the web tears. The affected layers are removed and clean paper is applied.

Small crumbs of adhesive that are deposited on the paper fabric before the dryer section lead to thin spots and holes in the web – this often results in breaks in the paper machine and costly production interruptions. Too many sticky impurities are one of the most common reasons that make an additional wire change necessary. Together with the downtime, the costs can quickly reach five figures.

This is why paper mills invest up to 3 million euros per year in various measures to remove sticky contaminants in the recycling process: firstly with screens that can separate even larger, undivided pieces – which is why polyurethanes and hot melt adhesives are usually no problem. Smaller particles are separated using centrifugal forces (“cleaners”). However, it becomes difficult with dispersions that disperse (redisperse) together with the fibres in the water and only reappear in the dryer section when the water evaporates. Various substances are said to help remove dispersed adhesives from the water, but so far there is no magic bullet.

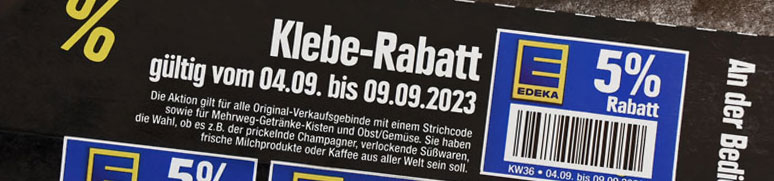

Stickers as a Permanent Source of Adhesives

INGEDE has investigated how the adhesives of discount stickers from various discounters behave in recycling. With sobering results.

First of all, it is not the individual stickers that a consumer carries home that are a real nuisance when it comes to paper recycling. Rather, it is the larger quantities that can be generated as printing waste, but also when several bundles are left over from distributing the weekly newspaper and are disposed of in the waste paper bin – or from the stairwell of an apartment block.

But even smaller quantities add up, which is why the Blue Angel for printed products and other eco-labels also requires that the removability of the adhesive applications used must be proven. This verification is possible using a method developed many years ago by INGEDE together with research institutes, INGEDE Method 12.

This is how INGEDE once again analysed discount stickers that appear as inserts in weekly publications. The result: the stickers from Edeka fail the test, and those from Netto pass with zero points, so no grounds for enthusiasm either: the EPRC Scorecard, the evaluation scheme of the European Paper Recycling Council, is a consensus that makes no insurmountable demands.

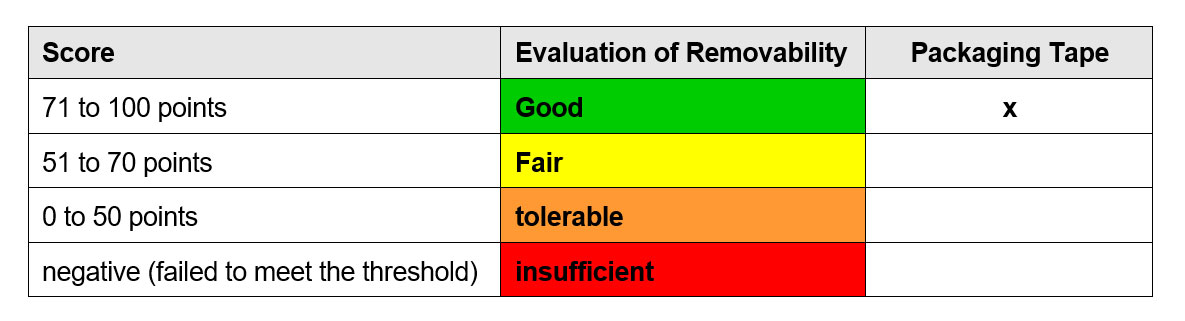

Adhesive tests: Many Packaging Tapes are Good

Over the past two years, many manufacturers have had their adhesive tapes tested for “recyclability” – with mostly “good” results

We remember the ubiquitous requests to remove the plastic tape from cardboard boxes before putting them (unshredded, please; folded at most) in the paper recycling bin. Why? Not because of the adhesive tape, which can be sieved off, but because of the adhesive. More and more adhesive tape manufacturers are now advertising that their products are unproblematic in the recycling process.

What makes a “recycling-friendly” adhesive tape? Firstly, PVC is of course taboo because the fumes produced during incineration are corrosive and can destroy exhaust systems (and potentially lead to the formation of polychlorinated dioxins). Then there is the proof that the adhesive used can be “easily” removed during recycling. This can be demonstrated using the INGEDE Method 12 presented above. A whole range of leading suppliers of packaging tapes have had their products tested and their adhesive removability confirmed, including e. g. Atlas Tapes (Greece) and Eurocel Sicad, PPM Industries SpA, and MAC Autoadesivi (Italy), as well as Supra-Ratiopac (Germany).

Adhesive tapes made of paper are often available that are tear-resistant to a certain degree, but can still be torn off by hand. As these are and must be wet-strength, they are screened in the same way as plastic adhesive tapes when the used paper or board is dissolved. In most cases, the adhesive used adheres so well to the tape that it is torn off together with the tape and does not interfere with the subsequent process.

INGEDE: Blue receipts must go in the residual waste!

Loss of brightness during paper recycling – black ink cannot be removed

In recent days, reports have caused confusion that blue receipts should be disposed of with paper for recycling, despite the well-known problems with recycling, as recommended by the German Environment Agency (UBA). As the problems these thermal papers cause during paper recycling have been known for many years, the UBA has now again updated a website from early 2020. The former recommendation “As long as the colour developer-free thermal paper does not pass the recycling tests, all thermal papers should be disposed of with the residual waste” has been replaced, the UBA now says: “Disposing of small quantities in paper for recycling, on the other hand, does not harm recycling.”

Developer-free thermal paper is a step in the right direction, as it no longer requires bisphenols, which are a health hazard. However, in a press release, even the manufacturer notes that these blue receipts are undesirable in paper recycling due to the black pigment. Still, it is assumed that the blue slips could be completely separated during paper sorting and only used in cardboard production. This is not the case – the blue-black papers can meanwhile be found everywhere in paper for recycling, and, even in the smallest quantities, contribute to a deterioration in the recycling result due to the high pigment load. This summer, an attentive incoming goods inspection at a paper mill was only just able to refuse a load of shredded office paper from entering circulation, which – interspersed with blue receipts – would have had the potential to turn up to a thousand tonnes of recycled paper unusably dark (see also INGEDE News July 2023).

INGEDE has been pointing out since 2019 that blue receipts, like all other thermal paper, do not belong in paper for recycling, but in residual waste. The paper mills represented in INGEDE now expect that retailers will also refrain from using misleading labelling such as “dispose of with paper for recycling” in future.

This article was updated from the original version on 20 December 2023 after the German Environment Agency changed its recommendation on the website” Fragen und Antworten zur Bonpflicht” (German only) on 15 December.

Andreas Rauscher is new Chairman of INGEDE

At its last general assembly, INGEDE elected the previous deputy chairman Andreas Rauscher new chairman

Andreas Rauscher has been Technical Managing Director at Steinbeis Papier since February 2022. He is responsible for technology, production, and research and development. He came to Glückstadt with a wealth of experience from the paper industry: Most recently, the 57-year-old worked for Zellstoff Pöls AG. As CEO of the Austrian company, he was in charge of pulp production and kraft paper production from mid-2018.

After graduating with a degree in process engineering, Rauscher was able to establish himself as an expert and manager in various management roles: He started his career at MD Papier in Plattling. His path led him to the UPM Group, first to Steyrermühl, and soon afterwards he took over the position of mill manager at the Schwedt site. As Technical Managing Director at a delfortgroup plant in Finland, he was able to emphasise his leadership skills and technical expertise. Andreas Rauscher thus recommended himself for the position of Managing Director at Steinbeis Papier – and thus also as a member of the INGEDE Board, where he had previously been responsible for public relations, among other things.

Imerys is now INGEDE Partner

“We are the world leader in mineral-based, high-quality, natural solutions which allow every step of the pulp, paper, paperboard and printing process to be optimized.”

High-performance pigments, such as calcium carbonates and kaolins, improve the printability and visual appeal of paper and board when used as a coating, with a focus on coverage, brightness and gloss. Functional filler pigments enhance runnability, improve surface properties and promote opacity and brightness. Talcs and bentonites are excellent environment-friendly solutions for a cleaner paper-making process.

A unique range of mineralized water-based barrier coatings is also available for board producers and converters to develop sustainable and innovative solutions as alternatives to PE lamination.

Mechanical and chemical pulp bleaching can be enhanced through the use of Imerys’ magnesium hydroxide bleaching additive, EcoBright™, which allows pulp producers to eliminate magnesium sulfate with significant caustic reduction and the potential to lower peroxide dosages in most systems. Additional benefits include reduced COD in the wastewater and less carryover of anionic charges to the paper machine.

Within INGEDE, Dr. Peter Biza from IMerys in Toulouse (France) will represent the company and take part in INGEDE’s working groups.

Dramatic decline in the production of graphic paper

The Association of the German Paper Industry (DIE PAPIERINDUSTRIE) points to an alarming situation in its 2023 half-year report on the German pulp and paper industry.

Compared to the same period last year, German paper production has fallen by almost 21 %. Sales fell by 19.1 % and turnover by 25 %. In comparison with other European countries, production in Germany fell even more sharply by -5.7 %.

During the recession, less is being bought, packaged and transported. In addition to graphic papers, cardboard and paperboard, which recently benefited from strong online trade and were among the digitalisation winners, are feeling the effects of this. This is having a particularly hard impact on graphic papers. As a result of digitalisation, the decline in print advertising, newspaper and magazine circulation has been noticeable for years. The production of graphic paper was reduced by 36.6 % in the last six months. Paper, board and packaging (-16.4 %), hygiene papers (-6.3 %) and technical and speciality papers (-7.8 %) also did not perform satisfactorily in the last six months.

The Cologne-based media company DuMont closed its printing centre in Cologne at the beginning of October. “Kölner Stadt-Anzeiger”, “Kölnische Rundschau” and the “Express” are now printed by Mittelrhein-Verlag in Koblenz. Around 200 employees are affected. DuMont justifies the closure with the “overall economic situation” as well as price increases for paper, electricity, and gas.

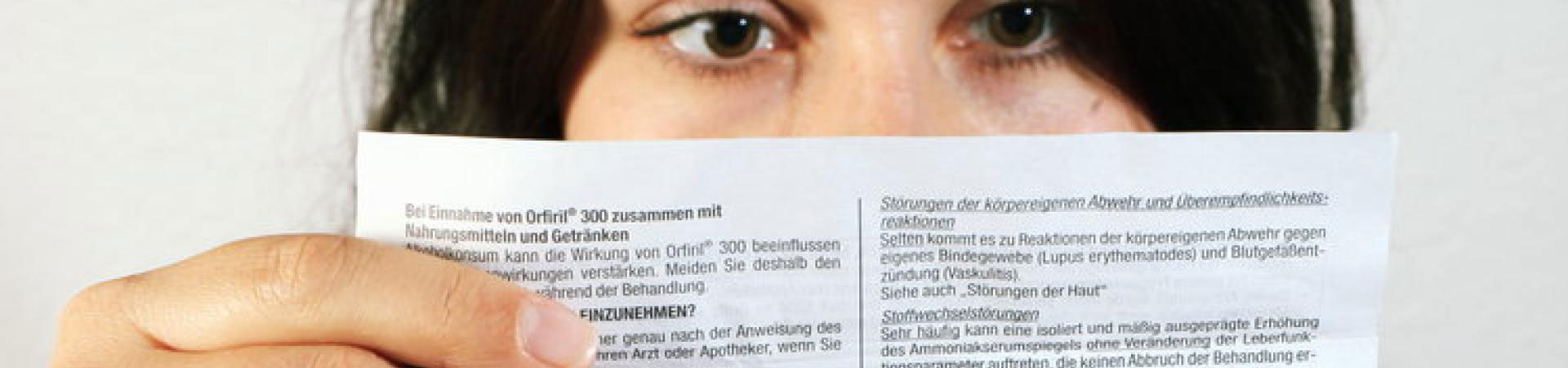

Intergraf damands:

Keep the printed package leaflet for medicine!

Draft EU directive on medicinal products criticised

Intergraf, the European umbrella organisation of national printing associations, is calling for the obligatory retention of the leaflet in paper form in the packaging. A press release states that the European Union should reconsider Article 63.3 of the proposed Directive on medicinal products and “emphasise the essential role of the package leaflet of medicinal products”. Article 63.3 proposes that patients should be able to request free printed copies of package leaflets that are only available in digital form.

The current draft of the Medicines Directive aims to ensure the accessibility and safety of patient information in a digital format, according to an Intergraf press release. While this goal is commendable, Eurostat 2023 data shows the stark reality – namely that 70.7 % of Europeans have only basic, little or no digital skills, while 7.5 % of European households do not even have internet access. (…)

More on the website of Intergraf

Apply for the 9th edition of European Paper Recycling Awards!

Every two years, the European Paper Recycling Awards distinguish European projects, initiatives or campaigns that change the way we recycle paper in Europe and support us in our ambitious paper recycling rate goals.

The competition is open to all entities based in Europe including schools, universities, NGOs, national and regional authorities, companies and associations.

There are two award categories:

1) Information and Education

2) Innovative Technologies and R&D.

Eligible projects, initiatives or campaigns will be evaluated based on the following criteria:

o Relevance and Originality,

o Achievements,

o Possibility to reproduce the project,

o Cost effectiveness.

CEPI is looking forward to receiving your applications here by 15 December 2023. The awards ceremony will take place in February 2024 in the European Parliament in Brussels.

The ceremony of the 8th Edition of the European Paper Recycling Awards took place on 29 June 2022 and was hosted by Ms Anna-Michelle Asimakopoulou, Member of the European Parliament.

For some time now, the guidelines for the Austrian Ecolabel (UZ-24) have also required proof of deinkability for varnishes, which can only be tested in combination with a printing ink. Most varnish manufacturers do not want to contribute to the costs of such tests, but leave this to the individual interested parties, which in Austria are the printing companies. The Austrian association is now supporting its member companies with a cost contribution of 300 euros.

Read more (in German)

Verband Druck & Medien Österreich

Paper & Biorefinery Graz

Every year, international experts of the value chain for wood, paper and pulp meet in Graz to discuss the topics that are of particular relevance for the future of our sector. You are cordially invite to join – on 15 and 16 May 2024!

Editing and all photos without attribution: Axel Fischer, INGEDE

SUBSCRIBE here to our monthly newsletter!