INGEDE News March 2022: Availability and quality of paper for recycling are the main topics at the INGEDE Symposium

- Calendar of Events

- INGEDE Symposium on Wednesday, March 9, 2022

- EnEWA: Fibres from packaging: – Finding new sources of recovered paper

- … and ODiWiP: Conserving resources in the paper industry

- Why are deinkers running out of white recycled fibers – the way to more sustainability in the circular economy

- Tork PaperCircle – closing the loop for paper hand towels

- No Blue Angel for blue sales slips – “Ökobon” into the residual waste!

- How to test recyclability? A webinar by the American SPC

- In addition: Food packaging recyclability factsheets vom Foood Packaging Forum

- and as a reminder: DIN SPEC 6745 „Papier, Pappe und Faserstoff – Recycling …”

- Personnel: Kati Weiß supports INGEDE’s office

- Hunkeler Innovation Days again in February 2023

- SUBSCRIBE here to our monthly newsletter!

INGEDE Symposium

on Wednesday, March 9, 2022

Paper after Corona, recovered paper shortage,

and increasingly poor quality:

Wide range of topics at the INGEDE Symposium

on March 9, 2022 in Munich and online

The recycling paper industry desperately needs raw material – fewer newspapers, less advertising due to the Corona pandemic and due to increasing electronic communication lead to decreasing quantities of graphic paper for recycling.

Furthermore, too much of the collected paper bypasses the sorting facilities and thus the deinking plants of the paper mills and goes directly towards packaging – here the demand keeps increasing due to “Amazonitis”.

Complex composite packaging is often not recyclable and therefore not sustainable, even if it is based on fibres. And white fibres in particular should be preserved where they add the most value. Even if sorting means effort, sorting is necessary to keep white fibres available for new white graphic papers, for hygiene papers and white topliners – and to prevent downcycling or at least to delay it as long as possible.

Availability and quality are the key topics at the INGEDE Symposium 2022, where experts will present possibilities for future sustainable recycling of raw materials: By certifying sorting facilities in order to avoid costly rejections and negotiations; by certifying paper and printed products for optimal recyclability, and by developing new sorting techniques to save more white fibres for the white cycle.

The INGEDE Symposium is planned as a hybrid event with participation in Munich according to the current rules (2G+), and at the same time online (still available – register now).

A preview of some selected topics can be found here in this issue of INGEDE News!

More details about the program at www.ingede.com/symposium.

Fibres from packaging:

Finding new sources of recovered paper

The EnEWA research project, funded by the German Federal Ministry of Economics and Climate Protection, aims to tap into previously unused or only partially usable sources of waste paper.

The Chair of International Production Engineering and Management (IPEM) at the University of Siegen and the Institute for Anthropogenic Material Cycles (ANTS) at RWTH Aachen University as well as the industrial partners LEIPA Group GmbH, PROPAKMA GmbH, STADLER Anlagenbau GmbH and Tomra Sorting GmbH are jointly researching how recovered paper can be obtained from the fractions of light packaging, commercial waste and residual waste and processed in a hygienically safe manner.

Today, the share of paper in light packaging comes mainly from discards. However, due to the increase in fibre-based packaging, which is coated in a similar way to used beverage cartons and contains food residues, these proportions will increase. The composition of commercial waste from fast-food restaurants, for example, will change accordingly.

Important elements of the project are sorting analyses from these waste streams, which are distributed geographically and seasonally across Germany. In January 2022, one of these analyses took place in a North Rhine-Westphalian sorting plant for light packaging. Alena Spies from ANTS will present the results at the upcoming INGEDE symposium.

Later steps in this project, which will run for a total of three years, are the semi-technical processing of the paper fractions with a process step for hygienisation, naturally accompanied by the corresponding analytics. The integration into the industrial process (keyword: water cycle) will also be considered.

The Federal Environment Agency, INGEDE and a number of other companies and organisations support and accompany the project. Remondis and Veolia, two well-known waste management companies, have not only made their sorting facilities available for the sampling, but have also agreed to co-finance the project. Further sampling will take place at the Stadtwerke Hamburg, which will provide additional extensive data material from their sorting facilities.

Andreas Faul

Read more: Press release of Aachen University

Conserving resources in the paper industry

Two research projects at the Institute of Production Technology at the University of Siegen (PROTECH) are to contribute to resource conservation in paper recycling.

The production of paper consumes a lot of energy, wood and water. The annual emission of around 10.6 million tonnes of CO2 in paper production in Germany corresponds to the emissions of around 4.5 million cars. The two research projects of the Chair of International Production Engineering and Management headed by Prof. Dr.-Ing. Peter Burggräf, ODiWiP (Optimised Recyclable Materials Cycle in the Paper Industry) and EnEWA (Energy Saving in Paper Production by Tapping the Value Chains of Waste Paper from Lightweight Packaging, Residual Waste and Commercial Waste), pursue the common goal of further reducing resource consumption in paper production and recycling with different approaches.

Why are deinkers running out of white recycled fibers – the way to more sustainability in the circular economy

Abstract of the presentation at the upcoming INGEDE Symposium

The use of recycled fibers in graphic products and the efforts of all partners in the value chain to produce recyclable products has been a prime example of responsible and sustainable circular economy for decades. The framework conditions, especially in the last 10 years, have made it anything but easy for Deinkers. An essential point is the availability of graphic recovered paper. The consumption and thus the availability of graphic products has been falling continuously for many years. At the same time, white recycled fibers are increasingly being used not only in graphic products, but also in non-graphic white paper and packaging segments, in tissue and in technical specialty papers. In 2021, this development in connection with the rapid recovery after the first Corona year resulted in massive supply restrictions for Deinking grades. The resulting standstills at mills using recycled fiber contributed to the paper shortage at printers.

The reason for the supply bottleneck was and is not the insufficient collection of used graphic products. The downcycling of white graphic products into brown packaging products, especially from collection in private households, is responsible for this. This development would not be necessary if some European countries, above all Germany, placed a little more value on clean separation of the secondary raw material flows. The presentation will show what needs to be changed in order to improve the recovery of white fibers and to ensure the availability of white recycled products in the future.

Thomas Krauthauf

Tork PaperCircle – closing the loop for paper hand towels

Abstract of the presentation at the upcoming INGEDE Symposium

Paper towels remain one of the most hygienic methods for drying hands. However, in terms of recycling and paper recovery, they are an untapped resource. Currently, less than 1 % of all paper towels are recycled. The reason: the wet strength agent that must be present in paper towels for them to do their job effectively requires a separate dissolving process.

Tork PaperCircle is a unique, award-winning, circular service that turns waste into new resources while reducing carbon emissions for paper hand towels. It involves many actors along the recycling value chain. It builds on a strong partnership and we know that it generates value for all actors involved.

By doing business differently Essity services meet demands and expectations of society and legislation as a strong contribution to circular economy. The service is used by more than 130 customers in 10 different markets.

essity

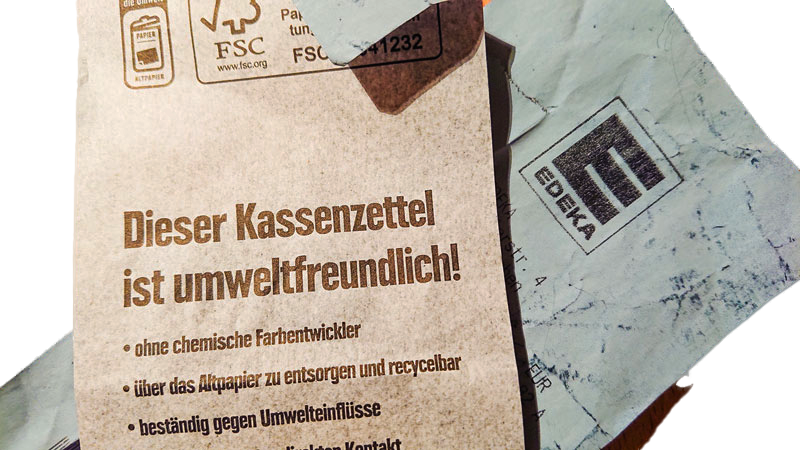

No Blue Angel for blue sales slips

At its winter meeting on 7/8 December 2021, the Environmental Label Jury decided on criteria for three new ecolabels, including a new ecolabel for thermal papers.

The primary goal of the new eco-label is to eliminate chemical ink developers that contain substances that are harmful to health or the environment.

However, there are still no thermal papers that meet the requirements of the new Blue Angel.

An extensive investigation by INGEDE on the new, colour developer-free sales slips (“Ökobon”) proved observations that have already been reported here several times (INGEDE News February 2020): Contrary to the claims of Lidl, Edeka & Co., the blue sales slips must not be disposed of with paper for recycling!

According to recent studies, a single receipt (1.5 grams) is enough to reduce the brightness of three kilograms of white paper by three points, as the black dye cannot be sufficiently removed during recycling.

On the website of the Federal Environment Agency, under the heading “Award Criteria”, there is a general text on the new Blue Angel “Environmentally Friendly Thermal Papers DE-UZ 223”), but the criteria adopted are not yet available. After the request of the paper mills that are members of INGEDE, the text states that only thermal papers that do not impair paper recycling can be awarded a Blue Angel.

Update April 2022: The criteria are now available on the Blue Angel Website.

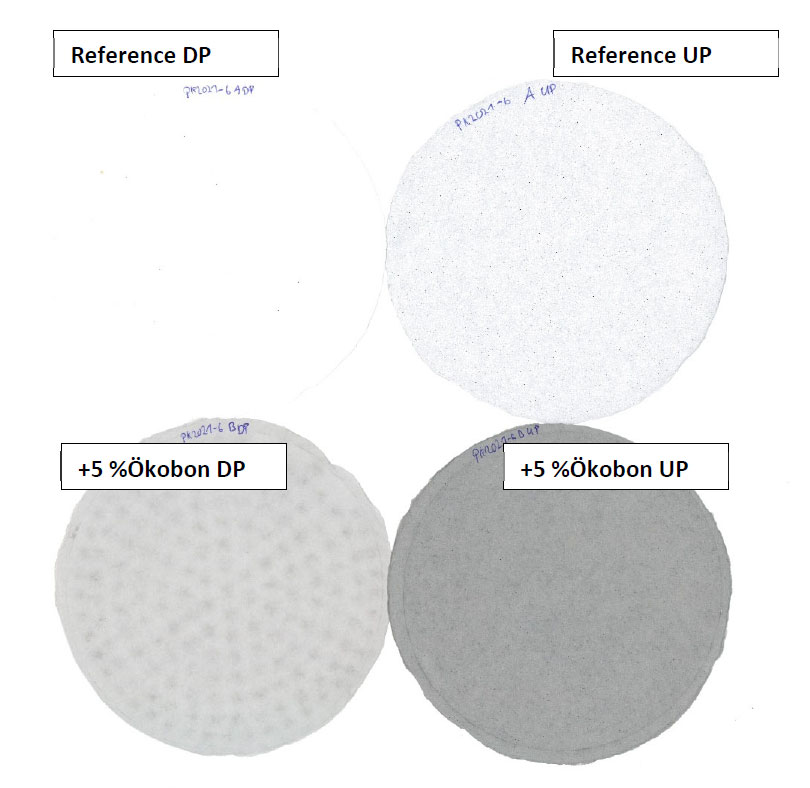

Already in 2019, experiments showed that the black ink from the blue receipts cannot be removed during recycling.

Already in 2019, experiments showed that the black ink from the blue receipts cannot be removed during recycling.

Right and wrong:

Yes, the blue receipt does not contain any chemical colour developers. But no, the blue receipt should never be disposed of with the paper for recycling! The black dye leads to massive loss of brightness during recycling.

Therefore: Blue sales slips (“Ökobon”) belong in the residual waste like all other thermal papers!

UP = undeinter Stoff (rechts), DP = deinkter Stoff

How to test recyclability? Background on different test protocols

Recording of a webinar from end of January

In this session we explored various paper recycling testing lab protocols and strategies from around the world. We included the perspective from labs in North America and Europe to better understand how these labs operate, potential synergies, and future needs as the role of innovation in paper packaging, testing requirements, and sustainability goals evolves at a rapid pace.

Speakers

Raw Materials Director, CEPI

Food packaging recyclability factsheets

The Food Packaging Forum (based in Zurich, Switzerland) published five fact sheets on packaging materials focusing on their recyclability. Fact sheets are available for plastic, paper and board, metals, glass and multimaterial packaging. Some issues concerning UV-printed materials are mentioned, such as “photoinitiators that were not completely converted during printing” as potential migrants.

Zur Erinnerung: DIN SPEC 6745

Das Deutsche Institut für Normung (DIN) hat die DIN SPEC 6745 mit dem Titel „Papier, Pappe und Faserstoff – Recycling – Bestimmung von klebenden und nicht klebenden Verunreinigungen in Altpapier-Halbstoffen und darauf basierenden Papieren mittels Nahinfrarot-Messverfahren“ veröffentlicht. Das in diesem Standard beschriebene Messverfahren verbessert das Recycling von Altpapier deutlich und trägt damit zum Aufbau einer Circular Economy bei.

Kati Weiß supports INGEDE's office

Seit Oktober 2021 verstärkt Kati Weiß das Team der INGEDE Geschäftsstelle in Bissingen.

Sie übernimmt den Aufgabenbereich von Elke Berger.

Ms Weiß can be reached in the morning via telephone at +49 7142 37522-21.

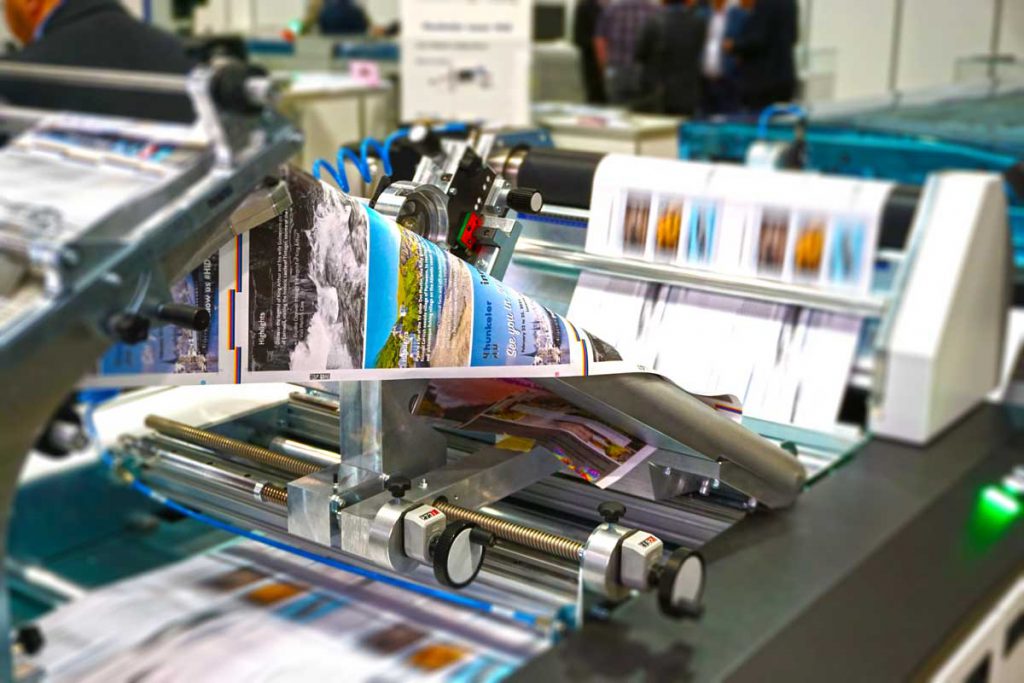

Hunkeler Innovation Days

After Corona-induced break back in February 2023

The Hunkeler Innovationdays are an important meeting place for the digital printing industry and are gaining in international popularity. Exhibitors, visitors and the trade press agree on this. The next edition has already been scheduled: The Hunkeler Innovationdays 2023 will again take place at the Lucerne Exhibition Centre from 27 February to 2 March 2023.

More details: Hunkeler Innovation Days

More events in our Calendar of Events

Bild: Fischer/INGEDE

SUBSCRIBE here to our monthly newsletter!