INGEDE News September 2024:

INGEDE represents every mill using paper for recycling

- Calendar of Events

- INGEDE now speaks for all users of paper for recycling

- Burgo upgrades from INGEDE Partner to INGEDE Member again

- Sonoco is now also a member of INGEDE

- Together: The INGEDE self-perception

- Henkel is new INGEDE Bronze Partner

- Landa prints are not deinkable: Many coloured specks in the recycled paper

- Blue Angel DE-UZ 237: New ecolabel for printing inks, inks, and toners

- Switzerland: Recyclability test certificate from rpk

- No ban on black printing ink in New York

- Events: INGEDE @Fachpack, @UV-Forum, 4evergreen Annual Event, INGEDE Symposium 2025

- SUBSCRIBE now: to our monthly newsletter!

INGEDE welcomes every mill using paper for recycling: Burgo is member again

The general assembly has decided on an expansion:

Now for all paper mills that process paper for recycling

Burgo’s Avezzano mill in Italy is the first new member of the new INGEDE

The availability and quality of paper for recycling are increasingly causing problems for recyclers – and not just for deinkers. INGEDE’s extensive activities in these areas have also been recognised by other paper mills without a deinking plant. Operating such a plant was previously a prerequisite for membership. By amending its articles of association, INGEDE has now opened its doors to all recovered paper processors. The first new member was already waiting in the wings: With the Avezzano mill, Burgo Papier, previously an “INGEDE Partner”, has officially become a member of INGEDE.

According to the revised articles of association, INGEDE’s objectives include

- to ensure the “environmentally compatible and efficientcareful use of paper for recycling in the production chain”

- encouraging, promoting, and coordinating research and development projects in the area of paper recycling and in technologies which have a substantial bearing on the recyclability of paper products including papermaking, printing inks, printing systems, adhesives, etc.

In addition to helping to shape regulations and standards such as the relevant ecolabels and ISO standards, the aim is also to educate decision-makers and the public about “environmentally and cost- sensitive behaviour to maintain the value chain”.

The broader spectrum of INGEDE’s work and its members is also reflected in the change of INGEDE’s full name: the International Research Association Deinking Technology has become the “International Association of the Paper Recycling Industry“.

Pictures: Burgo Group (3),

Axel Fischer for INGEDE (2)

Sonoco is now a member of INGEDE

From partner to INGEDE Member: core board made from recycled paper for textiles, paper, and adhesive tapes

Sonoco, formerly an associated partner of INGEDE, is happy to become a full member and welcomes the opportunity to work closer within this group on the topic of circularity.

The recycled paper industry is changing, and we are confident in finding the right approach and future-proof solutions based on sophisticated expert knowledge in INGEDE. We look forward to sharing our knowledge of non-deinking paper recycling and contributing to the association’s thought leadership.

Sonoco-Alcore, the paper division of Sonoco, produces coreboard made completely from recycled fibres. The paper mill in Cirié is situated close to Turin in Northern Italy. It has a headcount of 90 employees and a maximum output capacity of 120,000t annually. The mill produces 300 to 500 gsm coreboard on a tambour of 2500mm width, which can be cut down according to customer specifications between 60 mm and 1200 mm.

Together we recycle paper. Paper for recycling is our raw material. Together we solve problems: in collection and sorting, in labelling and certification, with contaminants and the recycling process.

Together when it comes to paper for recycling.

INGEDE.

Cooperation creates trust. Many issues affect all recyclers, whether for graphic paper or packaging. We work on them together with our partners.

Availability and the quality of paper for recycling are challenges that affect everyone who processes paper for recycling. We are working on the certification of sorting plants so that we can rely on the raw material. We are taking care of separate collection and cascade utilisation of fibre-based raw materials through to logistics and fire protection. We are in dialogue with manufacturers of printed products and packaging in order to maintain and improve the recyclability of these products.

We are active in the field of standardisation, with ISO, CEN, and DIN. We are active at national and European level, with Cepi and the European Paper Recycling Council (EPRC), the Blue Angel and the European Ecolabel, the Nordic Swan and the Austrian Ecolabel.

We actively promote paper and printed matter in times of digitalisation. We communicate successful paper recycling and the necessary prerequisites in social media, despite and especially because of this, and thus reach an international specialist audience.

All this only works together. Join us, become a member, become a partner!

INGEDE.

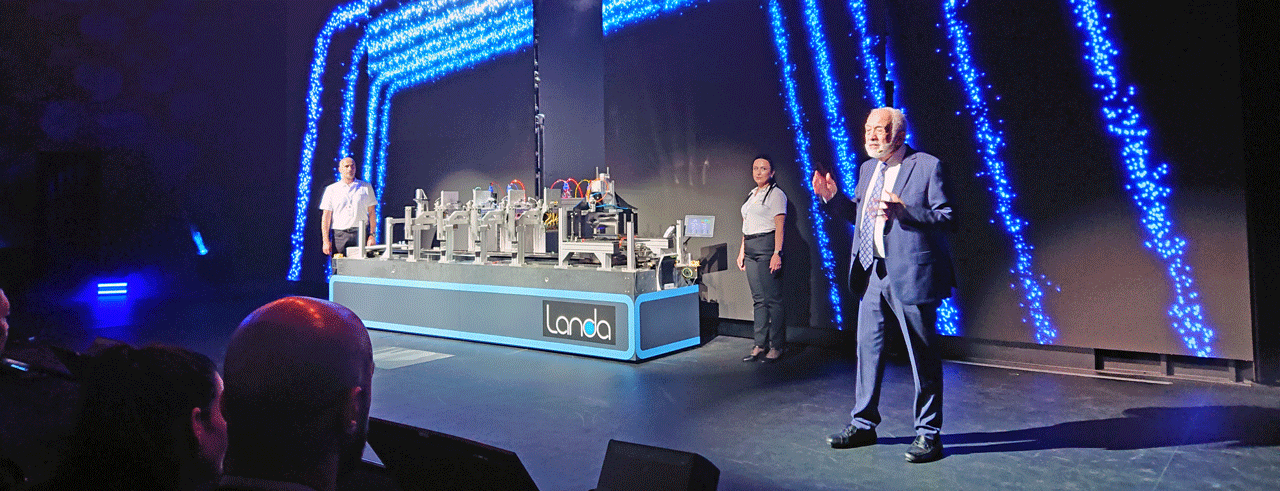

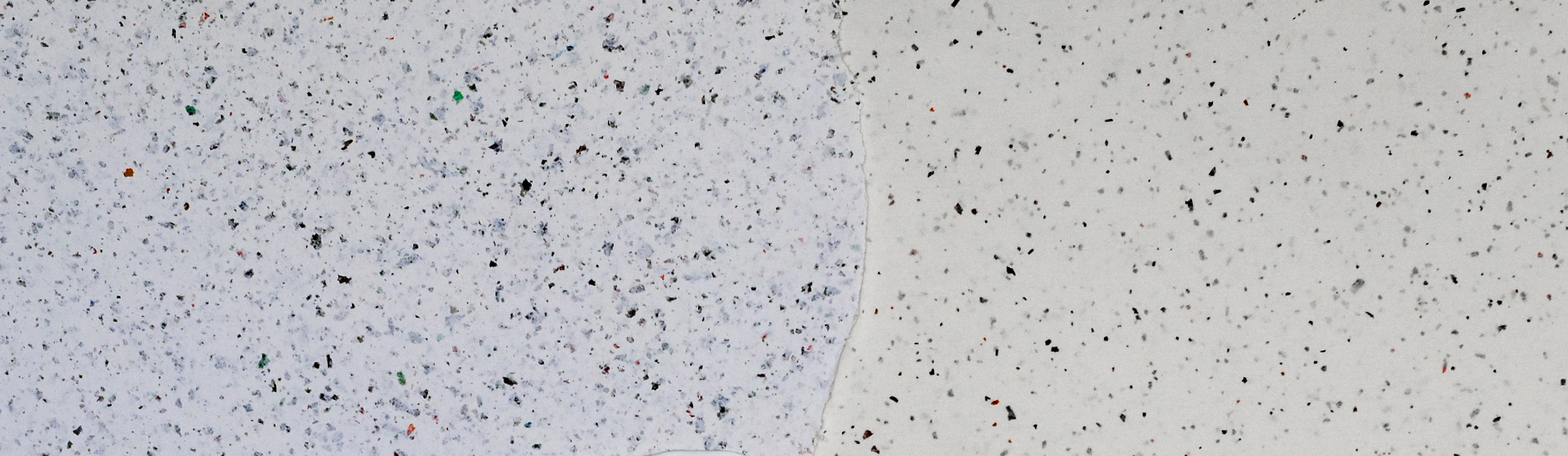

Many Coloured Specks in the Recycled Paper

Landa prints are not deinkable, contrary to what is stated on the website

The issue of Landa and deinkability has been dragging on since drupa 2016 – at the time, Landa had advertised good deinkability after INGEDE had received laboratory samples printed on one side in advance for testing and these had passed the test. However, the samples distributed at drupa subsequently failed the test with a sea of dirt specks: The inline UV coating drastically worsens the result.

Since then, Landa has claimed to have made changes to the printing ink that should lead to better deinkability. Landa also writes boastfully on its website: “Deinking a paper printed with Landa NanoInk® produces cleaner recycled paper than with any other ink.” (https://landanano.com/technology/sustainability/)

According to the latest research by INGEDE, this assertion is not tenable. On the contrary, paper printed using the Landa process (and particularly the waste produced during printing) must not be recycled with other graphic paper due to the high number of large, non-removable colour particles, but is only suitable for the production of corrugated cardboard raw material.

After drupa, INGEDE again analysed samples distributed there with the same devastating results as eight years ago (https://www.ingede.com/ingindxe/news/news2016/news1607-pub.pdf).

The reason for this is probably still the UV varnishing of the prints. The representative for Germany was not prepared to discuss co-operation or joint tests at drupa. In recent years, Landa had repeatedly avoided joint tests or a joint visit to Blueprint in Munich, where the first Landa S10P used for graphic applications in Germany is located.

The illustration below (section width approx. 20 cm) shows the lab sheets produced during the test, before (left) and after deinking.

As the sample maximally fails for large and small dirt points, the resulting score according to the EPRC Scorecard is -25 points (minus 25).

Blue Angel DE-UZ 237: New ecolabel for printing inks, inks, and toners for paper and cardboard on professional printing machines

Printing inks, inks, and toners for graphic print products such as books, newspapers, brochures, leaflets, and flyers are widely used; around 1.9 million tonnes of press and catalogue paper are printed every year in Germany (Papierindustrie 2023).

At the end of their utilisation, most paper products and therefore also printing inks, inks, and toners end up in the paper collection. In order to produce high-quality products from paper for recycling, impurities must be eliminated as far as possible. For this reason, printing inks, inks, and toners should be easy to remove from the printed product.

The manufacture and use of printing inks, inks, and toners can be associated with environmental and health impacts due to the use of hazardous substances. Toxic, water-polluting and persistent substances can end up in surface waters or in recycled products via recycled paper fibres. Hazardous substances include, for example, heavy metals and amines from dyes. Environmentally hazardous persistent substances include perfluorinated and polyfluorinated chemicals (‘PFAS’), which are used to increase abrasion resistance. Substances that hinder the reusability of paper fibres are mineral oil hydrocarbons and their contamination by polycyclic aromatic hydrocarbons (PAHs). These substances are either completely or largely excluded from products bearing the eco-label.

The requirements of the new Blue Angel ecolabel for printing inks, inks and toners guarantee that the products have a lower environmental and health impact. Hazardous ingredients are minimised and the printing inks can also be easily removed from the fibres during paper recycling and enable fibre recycling with fewer harmful substances. Some printing inks already contain oils based on renewable raw materials instead of mineral oils. Renewable raw materials should be sourced from certified sustainable production in order to preserve biodiversity and contribute to climate protection.

The new Blue Angel is a B2B ecolabel for use in the commercial sector and has been closely harmonised with the Blue Angel for printed products. It is intended to make it easier for print shops to certify their products as environmentally friendly print products (DE-UZ 195). The ecolabel is intended to recognise printing inks, inks, and toners that are primarily characterised by the following health and environmental protection criteria:

- low pollutant

- support high-level paper recycling

More details (award criteria): Printing inks, inks and toners for paper and cardboard on professional printing machines (DE-UZ 237)

Cutting gas consumption: Blue Angel also for LED web offset printing

At the summer meeting of the Blue Angel Ecolabel Jury, it was also decided to extend the scope of the Blue Angel for printed products (DE-UZ 195) to include LED-UV web offset printing. This is intended to honour the switch from gas drying, which is more harmful to the climate, to LED-UV printing. However, this does not apply to UV sheet-fed offset printing, as there are no similar advantages here compared to other printing inks. For this reason, the photoinitiators used will continue to be excluded.

The revised criteria are to be published shortly.

Ergebnisse der Sitzung der Jury Umweltzeichen im Sommer 2024 (German only)

Henkel is now an INGEDE Partner

In addition to well-known detergents and other consumer brands, Henkel is the global market leader in adhesives

With its brands, innovations and technologies, Henkel holds leading market positions worldwide in the industrial and consumer business.

With its Adhesive Technologies business sector, Henkel is the global market leader in adhesives, sealants, and functional coatings. With Consumer Brands, the company is a global leader in many markets and categories, particularly in detergents and cleaning products as well as in the hair sector. The company’s three largest brands are Loctite, Persil and Schwarzkopf.

In the 2023 financial year, Henkel generated sales of more than 21.5 billion euros and adjusted operating profit of around 2.6 billion euros. Henkel’s shares are listed on the DAX. Henkel has a long tradition of sustainable action, and the company pursues a clear sustainability strategy with specific targets. Henkel was founded in 1876 and today employs a diverse team of around 48,000 people worldwide – united by a strong corporate culture, shared values and the corporate purpose: “Pioneers at heart for the good of generations”.

Mr Philippe Blank and Mr Arne Jost will represent the company within INGEDE and participate in the INGEDE Working Groups.

More information: www.henkel.com

All INGEDE Partners and more about the INGEDE Partner programme here.

‘We are aware that our adhesives find their way into paper mills as a part of fibre-based packaging in various forms after collection and, if necessary, sorting. Henkel would like to accompany and support the processing of fibre-based packaging with its expertise and be available to the industry as a competent partner,’ explains Arne Jost, Senior Manager Circularity Packaging Henkel Adhesive Technologies.

Switzerland: Recyclability test certificate from rpk

Positive test confirmation from the Swiss Recycling Paper and Cardboard Association

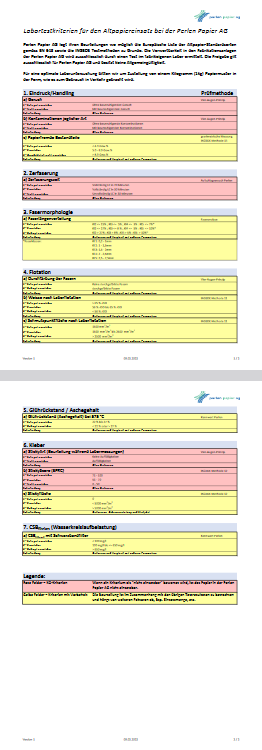

‘This product has been tested and is suitable for the recycling of paper for recycling and cardboard in Switzerland. The Association Recycling Paper and Cardboard (rpk) carries out various tests on the recyclability of paper and cardboard products. In each case, this assessment relates to recycling at the paper mills Aarepapier AG (Model Group), Perlen Papier AG and Thurpapier AG (Model Group). It does not replace in-depth laboratory analyses, as offered by several foreign laboratories.

The sole purpose of an assessment by rpk is to examine whether the submitted materials can be processed on the equipment of the paper mills mentioned above. It is possible that a feedback on the recyclability of a product by the technical commission does not correspond to the statements of foreign laboratories or manufacturers. A distinction must be made here between an analytical examination of a material and its actual use in mass production.

Source: Verein Recycling Papier und Karton

More: www.altpapier.ch (Materialprüfung, German only)

No ban on black printing ink in New York

Carbon black, the black pigment in printing ink, was on the hit list of a draft law with extensive regulations on extended producer responsibility (EPR) for packaging.

Printers and packaging manufacturers in New York State are relieved: A long-discussed bill failed to make it to the voting stage before the legislature adjourned. This means that the EPR programme for packaging, which would have included requirements for the reduction of packaging, the use of recycled materials and a ban on certain chemicals classified as toxic – including the use of carbon black, such as black printing ink or black-coloured plastic.

Initially, it was ‘only’ about packaging. But alarm bells started ringing among the respective organisations: Together with other associations, the PRINTING United Alliance presented the importance of carbon black as a colour pigment in a large number of documents. A ban on carbon black as an ingredient not only threatened print shops that produce packaging or labels, but also meant that no company would be allowed to sell products containing black ink or four-colour printed images in the state of New York.

As the draft ban did not include a threshold, the use of recycled packaging for new packaging would also have been banned, as the pigment residues in the recycled material alone would have led to exclusion. ‘The carbon black used in printing inks is not toxic,’ states the Alliance. ‘This has been confirmed by several regulatory authorities, including the Occupational Safety and Health Administration (OSHA).’

A topsy-turvy world: while black printing ink is supposed to be classified as toxic in New York State, the same ink is considered virtually edible by certain labels that claim to protect the environment and health.

Read more:

https://www.printing.org/content/2024/06/11/carbon-black-survives-assault-ban-in-new-york-state

https://www.diepresse.com/591105/kann-man-druckerschwaerze-essen (German only)

Events:

INGEDE @Fachpack, @UV-Forum

Das etablierte Anwenderforum UV-Druck lädt am 5. November 2024 erneut zum großen Branchentreffen nach Aschheim ein. Gemeinsam mit ausgewiesenen Expertinnen und Experten blickt die Fogra auf die Trends und Herausforderungen des UV-Drucks und freut sich auf den persönlichen Austausch in München!

Axel Fischer (INGEDE) wird hier am 5. November die neuesten Erkenntnisse zum LED-UV-Druck in Zusammenhang mit Papierrecycling und Deinking vorstellen.

FACHPACK und Pacoon mit Pavillon

„Alternative Verpackungslösungen“

24.–26. September 2024 im Messezentrum Nürnberg

Begleitet wird die Präsentation der Aussteller in der Messehalle 3 vom Forum SOLPACK 5.0, das sich nachhaltigen Verpackungslösungen widmet. Ein vielfältiges Programm und spannende Vorträge erwartet die Messebesucher an allen drei Messetagen. Im Forum SOLPACK 5.0 steht jeder Messetag unter einem Leitthema mit Kurzvorträgen.

🔄 Pilotprojekt Dänemark/Aarhus: Statt Mülleimer, Mehrweg-Rücknahmestellen im öffentlichen Raum | Sven Hennebach (TOMRA).

📝 Papierverpackungen: Gestrichen, bedruckt, lackiert, laminiert und verklebt und wie das Ganze auch rezyklierbar gestaltet werden kann | Axel Fischer (INGEDE).

🌳 vieles mehr über #Mehrweg, #Recycling und innovative #Faserverpackungen

4evergreen Annual Conference

New Horizons for Fibre-based Packaging Circularity

6 November 2024 – Brussels & Online

On 6 November, the 4evergreen Alliance will host its annual event in Brussels and online. This year’s Conference, ‘New Horizons for Fibre-based Packaging Circularity,’ also marks the alliance’s fifth anniversary. It will be a special occasion to reflect on 4evergreen’s collective journey towards circularity, take stock of accomplishments so far, and explore together where the next priorities lie.

In addition to exploring how 4evergreen’s tools and guidelines can boost the recycling rate of fibre-based packaging, the event will bring together representatives from the whole value chain, policymakers, and other key stakeholders to discuss the latest developments and challenges in the sector. Stay tuned for more information.

Registrations open at the beginning of September – be among the first to secure your spot!

4evergreen will also attend FachPack, in Germany. Between 24 and 26 September, the 4evergreen alliance will showcase its toolkit in a joint booth with ProCarton and FFI, highlighting the life cycle of carton. During the two-day event, ambassadors of the alliance will take the stage twice during the Packbox session – Packaging for the Future and the 4evergreen Roundtable.

Editor/all pictures without other credits: Axel Fischer, INGEDE

SUBSCRIBE HERE to our newsletter!