Deinkable Liquid Toner, Deinkable Inkjet: New Recycling Friendly Developments

Dry toner and solid ink remain good deinkable

INGEDE Press Release 1/2012

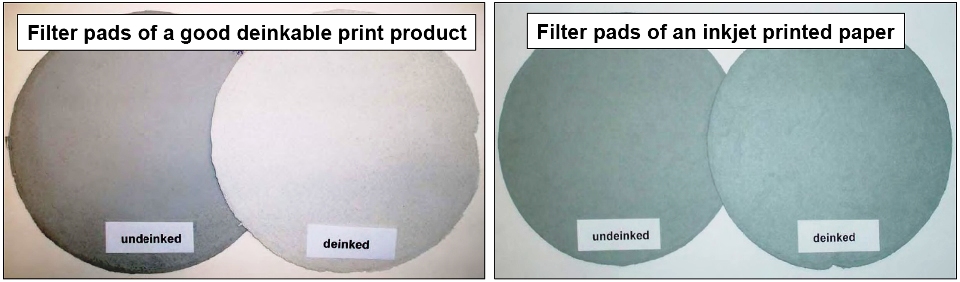

What makes a digital print sustainable? No, not if the printer uses water-based inks – on the contrary, nearly all products printed with water-based inks currently create severe problems in the recycling process: When a paper mill wants to remove the ink (to deink the paper) in order to produce new, bright paper, dyes and small pigments cannot be removed. The result: paper fibres become grey; the mill struggles to achieve the required quality. Especially dye based inks will colour the pulp in small amounts – like a single red sock turns a whole wash load pink. But now new options are in sight to make inkjet inks better deinkable.

Liquid toner has also been a major challenge for paper recycling. HP Indigo prints have been the first digitally print products to cause severe damage in a paper mill. In 2010, more than 100,000 Euro damage occurred after photobook overprint speckled almost eight hours production of high quality recycled paper. Since then, Indigo overprint is banned from the graphic paper recycling stream; it has to be collected and processed separately.

A new liquid toner technology presented at drupa using a different polymer system seems to work much better: First deinking results from Xeikon’s Quantum technology show results in the same range as dry toner. As soon as they are available, INGEDE will perform tests with typical production prints.

On the way towards deinkable inkjet inks

Also inkjet prints can become deinkable – this has been shown within a cooperation of INGEDE with the Austrian inkjet specialist SEPIAX. There, researchers have developed resin coated pigment particles that can be dispersed in water just like standard pigments; but after printing stick steadily on different surfaces – and can be removed from paper printed with them. The pigment particles agglomerate to form aggregates that have the right size and surface properties for the deinking process. The first laboratory test with these inks on uncoated newsprint without further optimisation already led to deinkable prints. Since then the ink has been improved for newspaper printing, a first printer to be presented will take until later this year.

Currently only a few special systems for water-based inkjet deliver prints that do not create problems: They either use a specially coated paper that absorbs the ink, or a pre-coating of the paper during the printing process to ensure instant coagulation of the pigmented ink particles (Fujifilm’s JetPress 720). Of the dye based inks, that is most of the current market, none can be deinked in the production of recycled paper today.

Preliminary tests with HP’s inkjet inks of the next generation introduced at drupa showed promising results on certain papers. As the tests have been performed with simplex prints and a low coverage only, they have to be confirmed with more typical prints as soon as these inks are being used in the field.

Dry toner and solid ink remain good deinkable

With a total of about 40 certificates for deinkability issued today, INGEDE sees dry toner and solid ink (non-aqueous inkjet) to be good deinkable generally independent from the paper used.

4 May 2012

INGEDE is an association of leading European paper manufacturers founded in 1989. INGEDE aims at promoting utilisation of recovered graphic paper (newsprint, magazines and office paper) and improving the conditions for an extended use of recovered paper for the production of graphic and hygiene papers.

Links:

![]() This press release for download

This press release for download

![]() This press release will soon be available also in German and

This press release will soon be available also in German and ![]() in French

in French

![]() Earlier press release about problems with liquid toner

Earlier press release about problems with liquid toner

![]() Earlier press release about deinkable inkjets at IPEX 2010

Earlier press release about deinkable inkjets at IPEX 2010

![]() The “European List of Standard Grades of Recovered Paper and Board“

The “European List of Standard Grades of Recovered Paper and Board“

![]() More information is available in the Deinking Digital Prints section of INGEDE’s website

More information is available in the Deinking Digital Prints section of INGEDE’s website

![]() CEPI has published “Guidelines for Responsible Sourcing and Supply of Recovered Paper”

CEPI has published “Guidelines for Responsible Sourcing and Supply of Recovered Paper”