Deinkable Ink for LE- and LED-UV Printing Introduced at the INGEDE Symposium

Current cross-linked inks are difficult to remove in the deinking process

INGEDE Press Release 1/2019

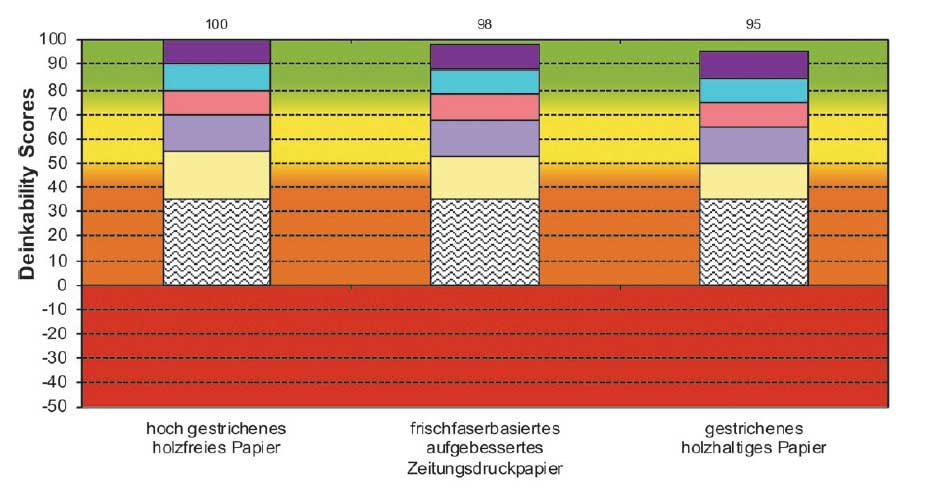

No more coloured dots in the recycled paper: Just because the curing radiation is being generated by energy-saving LED, UV printing inks are less environmentally friendly than the marketing suggests. They leave coloured dots in the newly made paper and thus can severely damage the recycling process – because they can hardly be deinked. This is about to change: At the INGEDE Symposium in Munich, Thomas Glaser (Siegwerk) and Peter Hengesbach (Stora Enso) presented extensive investigations into a new printing ink. This is equally suitable for LED- and low energy UV printing (H-UV, LE-UV, e. a.) as well as for conventional UV printing – and is excellently deinkable.

Deinkable ink is on the market

Siegwerk’s cooperation with the research department of INGEDE member Stora Enso began as early as 2017. Meanwhile, the deinkable LED UV colour is on the market. But the development continues: “We see even more potential,” says Glaser, Head of Technology Sheetfed at Siegwerk. “We are working on other deinkable UV and LED UV products.”

Other UV-curing inks rarely meet the criteria for good recyclability. Almost all previously studied colours leave significantly too many ink particles in the recycled paper. Paper printed with UV-curing inks can thus impair the deinkability of entire recovered paper batches. Therefore, such UV prints must be collected and disposed of separately at the point of contact where they occur (for example, printers’ waste). However, what once left the print shop can practically no longer be recognized and separated during collection and recycling.

Vegetable oil is not always good: Inks have to be tested carefully

Different inks behave differently in the deinking process. Together with INGEDE, colour manufacturers are therefore looking for ways to replace poorly deinkable inks with more recycling-friendly solutions. Cross-linked particles due to their size, flexibility or surface properties can neither be separated mechanically (screens) nor by flotation. Also some vegetable-oil based inks create problems, because they polymerise when drying and cling closely to the fibres – this again leads to dirt specks in the recycled paper.

Another cross-linked challenge is polyethylene liquid toner (HP Indigo), currently used for most of the photobooks. This is a thin plastic film rather than a conventional printing ink. During the recycling process, this film breaks into snippets, which cannot be removed sufficiently. These snippets have already led to significant damage in a paper mill, since then photobook printer waste must not be mixed with graphic paper for recycling and at best be used for corrugated board.

INGEDE is an association of leading European paper manufacturers founded in 1989, celebrating 30 years of support for paper recycling and deinking in 2019. INGEDE aims at promoting utilisation of recovered graphic paper (newsprint, magazines and office paper) and improving the conditions for an extended use of recovered paper for the production of new graphic paper, hygiene paper, and white top liner and folding boxboard.

4 March 2019

International Association of the Deinking Industry (INGEDE)

Public Relations

Oetztaler St 5 B

81373 München

Germany

Tel. +49 (89) 769 2332

info at ingede.com

Links:

![]() This press release for download

This press release for download

A press release by Siegwerk about the new deinkable LED-UV ink is here on the Siegwerk website.

INGEDE Press Release 1/2015: Low-Energy and LED-UV Printing is Not Necessarily Environmentally Friendly

The illustrations are available in higher resolution on request.